ISO 8: Defining Cleanroom Classification Guidelines

ISO 8: Defining Cleanroom Classification Guidelines

There are 9 ISO classifications, ISO 1, ISO 2, ISO 3, ISO 4, ISO 5, ISO 6, ISO 7, ISO 8, and ISO 9. ISO 1…

What Is A Cleanroom?

A cleanroom is a controlled space where the number, concentration and size of airborne particles are classified and tightly maintained to create a sterile environment.

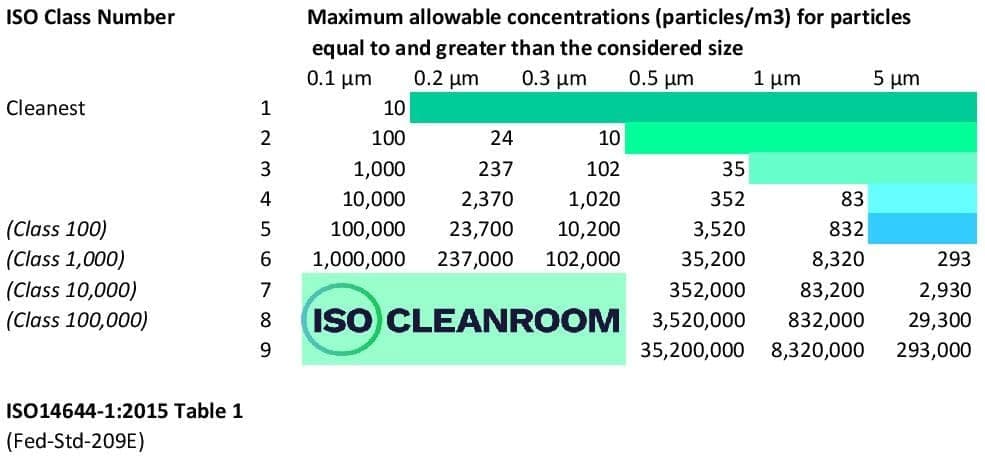

There are 9 ISO classifications, ISO 1, ISO 2, ISO 3, ISO 4, ISO 5, ISO 6, ISO 7, ISO 8, and ISO 9. ISO 1 is considered the cleanest while ISO 9 is considered the dirtiest. The table refers to the concentration of particles in a 1 cubic meter sample according to particle size as a micrometer or micron μm.

Table 1 of the ISO14644-1:2015 shows each classes maximum limit of air cleanliness by particle concentration.

What is an ISO 8 Cleanroom?

Before choosing an ISO classification, determine what size and number of particles can negatively affect your experiment, procedure or process.

An ISO 8 cleanroom has to go through the ISO 9 classification first. An ISO 8 classification requires that the air contain less than 3 520 000 particles >0.5 micron per cubic meter, less than 293,000 >5 micron per cubic meter. In order to achieve this you will need a series of filters for example a G4 and a H15 and it is recommended that you dilute the particulate levels by achieving a complete air change rate of up to 60 air changes per hour.

Why Do You Need an ISO 8 Cleanroom?

ISO 8 cleanrooms are used to protect products and procedures that are sensitive to a particular size and number amount of particle size. Industries that might require this level of cleanroom include aerospace, automotive, aviation, chemicals, defence, digital, technology and computer services, pharmaceutical, electronics, machinery and parts, life sciences, oil and gas production, research and innovation, space and lots more.

How To Get an ISO 8 Cleanroom?

One of the main design differences between an ISO 8 cleanroom and other, cleaner classes is that the ISO 8 Cleanroom does not require an airlock. However we usually advise you do still use an airlock for gowning as it aids your SOP and compliance. It uses a non-unidirectional airflow and goes through up to 60 air changes per hour.

How to Maintain an ISO 8 Cleanroom?

ISO 8 Cleanroom requires extensive care and maintenance. This is usually done with:

- Constant Positive Pressure

- Careful Material Selection

- All Personnel wearing PPE

- Air Filtration and Dilution

Do’s and Don’ts Inside a Cleanroom

- Do wipe all surfaces regularly to remove contamination. This should form an integral part of your SOP.

- Do keep all doors closed to maintain positive pressure.

- Do clean everything that’s being brought inside the cleanroom

- Do make sure all personnel wear personal protective equipment (PPE) over their clothes before going inside the cleanroom

- Don’t bring unnecessary objects inside the cleanroom. It is more for you to clean and reduces air flow.

- Don’t bring shedding materials into the cleanroom eg cardboard and natural fabrics.

- Don’t eat or drink in your cleanroom.

- Don’t turn the filtration off. This breaks the protocol as particulate can now enter your environment. You must maintain positive pressure.

Are you looking for a cleanroom? Contact us now to know more!