ISO 7: Defining Cleanroom Classification Guidelines

ISO 7: Defining Cleanroom Classification Guidelines

What Is A Cleanroom? The ISO 14644 series defines a cleanroom as a “room within which the concentration of airborne particles is controlled and classified, and which is designed, constructed and operated in a manner to control the introduction, generation and retention of particles inside the room". There are 9 ISO classifications, ISO 1, ISO…

What Is A Cleanroom?

The ISO 14644 series defines a cleanroom as a “room within which the concentration of airborne particles is controlled and classified, and which is designed, constructed and operated in a manner to control the introduction, generation and retention of particles inside the room”.

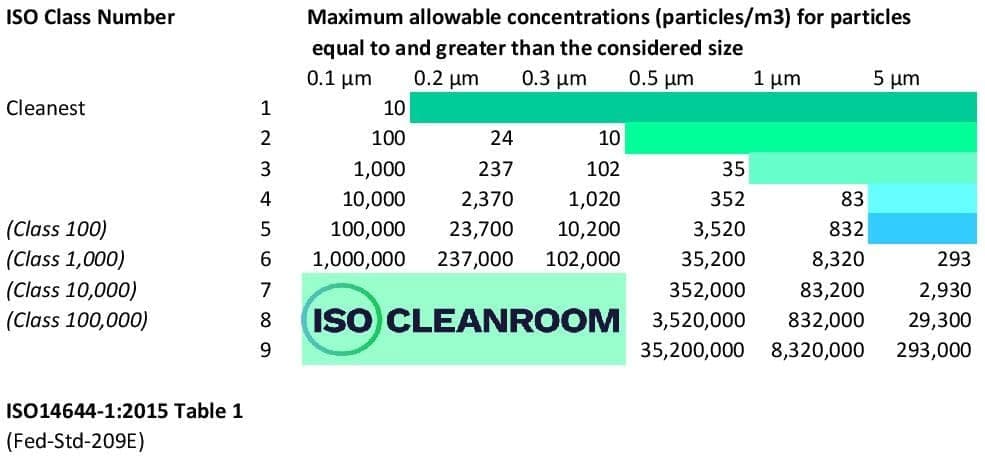

There are 9 ISO classifications, ISO 1, ISO 2, ISO 3, ISO 4, ISO 5, ISO 6, ISO 7, ISO 8, and ISO 9. ISO 1 is considered the cleanest while ISO 9 is considered the dirtiest. ISO 14644 provides us with a series of tables showing the maximum permittable particles at varying sizes for each ISO classification. The particles are categorized in number of micron (μm) particles per m3 of air.

ISO 14644-1:2015 Table 1. Please feel free to download.

What is an ISO 7 Cleanroom?

In the validation of an ISO 7 cleanroom a light scattering particle counter is used to sample the air at numerous points to ensure that that the air contains less than 352 000 particles equal to or greater than 0.5 micron per cubic meter and 2,930 particles equal or greater than 5 micron per cubic meter. An anemometer is also used to record that the room is achieving 30-60 HEPA filtered air changes per hour.

Some industries still refer to the old American Federal Standard 209E and so you might hear an ISO 7 cleanroom be referred to as class 10,000.

The EU GMP Annex 1 Class C classification is equivalent to ISO 14644 Class 7.

An important and often overlooked piece of work that should be thoroughly exhausted before specifying a cleanroom is to determine what size and number of particles can negatively affect your experiment, procedure or production.

Why Do You Need an ISO 7 Cleanroom?

ISO 7 Cleanrooms are used in almost every industry. Electronics manufacturers, advanced engineering, particularly those working with composites, Medical device manufacturing, for example, are all extremely sensitive to sub-micron particles.

The Pharmaceutical industries might use a GMP Class C or ISO 7 cleanroom for the filling of products or preparation of solutions that are unusually at risk of contamination.

How To Get an ISO 7 Cleanroom?

The ISO 7 Cleanroom is the most commonly used classification. As it requires a lower number of air changes it is not as expensive to build and requires less energy to run when compared to the classifications below.

It requires an airlock at any entry point, control of both the air in and also the air out so as to be able to control the internal pressure which should be around +25 to +30 pascal. An ISO 7 cleanroom will go through 30-60 air changes per hour. An ISO 7 cleanroom can use numerous construction materials, hard wall, monobloc, PVC, Glass etc the main feature of these materials being that they are smooth and resilient to the most common detergents and so easy to clean.

How to Maintain an ISO 7 Cleanroom?

Maintaining an ISO 7 Cleanroom requires extensive care. This is usually done with:

- Constant Positive Pressure

- Proper Material Selection

- All Personnel wearing PPE

- Air Filtration and Dilution

- A thorough and monitored cleaning schedule

- A detailed monitoring plan

Do’s and Don’ts Inside a Cleanroom

- Wipe all surfaces regularly to remove contamination

- Keep all doors closed to maintain positive pressure

- Clean all equipment that’s being brought inside the cleanroom

- Have all personnel wearing personal protective equipment (PPE) over their clothes before going inside the cleanroom

- Don’t bring unnecessary objects inside the cleanroom

- Don’t overload the floor area of the cleanroom

- Don’t eat or drink in your cleanroom

- Don’t turn off the HEPA fan filter units

Are you looking for a cleanroom? Contact us now to know more!