The Art of Gowning: Why Cleanroom Protocol is the 'Yoga' of Manufacturing

The Art of Gowning: Why Cleanroom Protocol is the 'Yoga' of Manufacturing

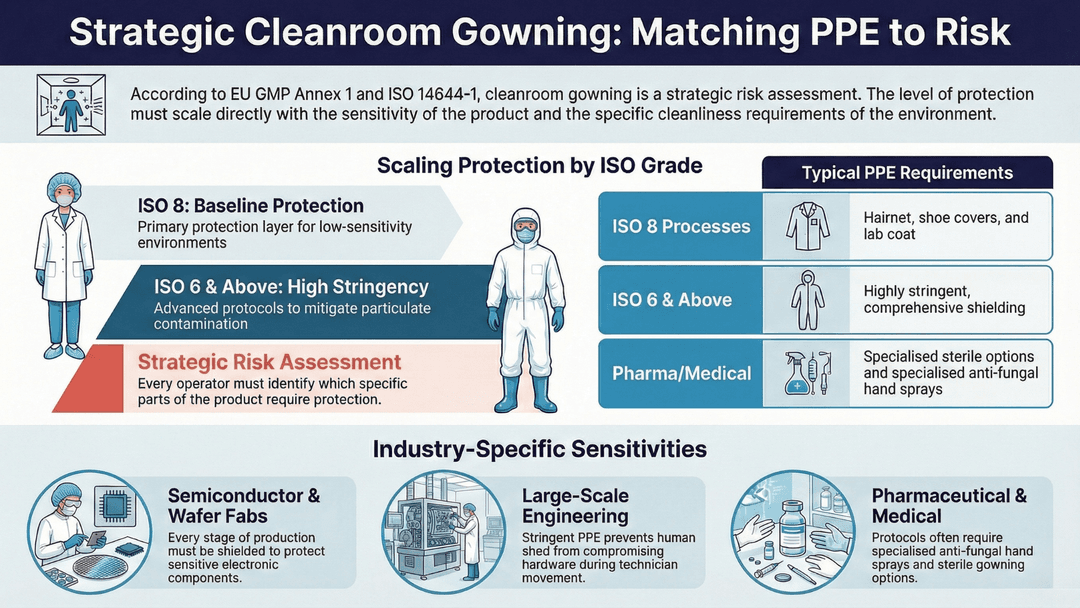

The requirement for gowning varies considerably depending on the cleanroom classification. Whether you are operating in an ISO 8 environment with basic hygiene requirements or a high-spec ISO 6 facility, the process is a disciplined sequence of movements designed to protect your product from the greatest source of contamination: the human operator.

Risk Assessment: Matching PPE to Your Process

According to EU GMP Annex 1 and ISO 14644-1, gowning is essentially a strategic risk assessment. For ISO 8 processes, requirements might be as simple as a hairnet, shoe covers, and a lab coat. However, as you move toward ISO 6 and above, the stringency increases.

The question every operator must ask is: Where is the sensitivity in my product, and what part of it needs protection? In the semiconductor industry or wafer fab production, every stage must be shielded. Similarly, in large-scale engineering, where technicians move above and around components, stringent Personal Protective Equipment (PPE) is vital to prevent human shed from compromising the hardware. In the pharmaceutical and medical sectors, protocols become even more specialised, often requiring anti-fungal hand sprays and a choice between sterile and non-sterile gown options.

pharmaceutical and medical sectors, protocols become even more specialised, often requiring anti-fungal hand sprays and a choice between sterile and non-sterile gown options.

The Gowning Sequence: From ‘Civilian’ to Sterile

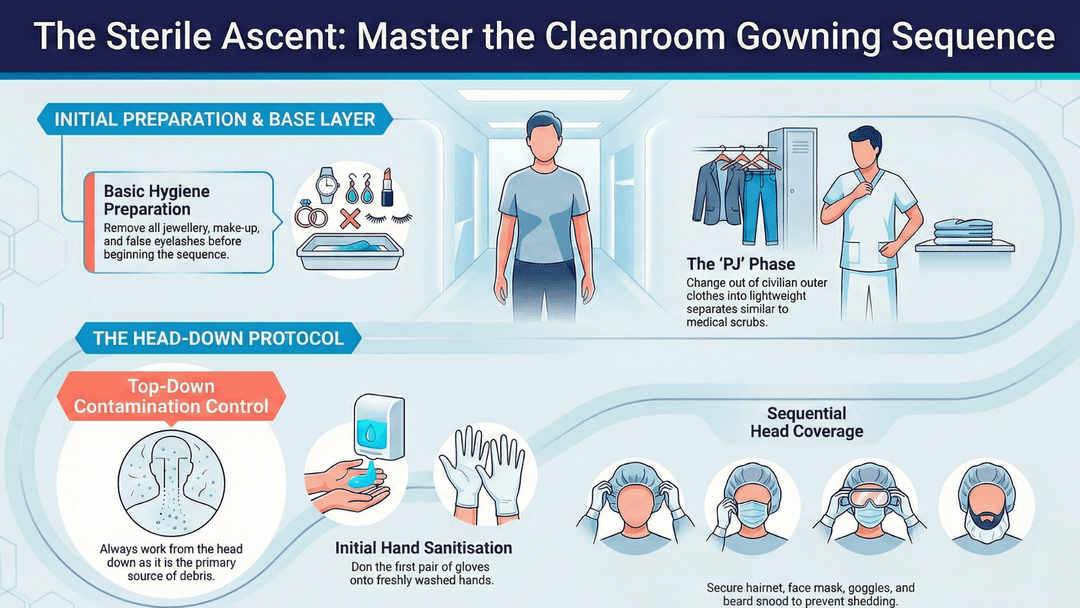

Gowning is far more comprehensive than simply putting on a suit; it is an all-embracing term covering preparation, technique, and the physical transition into the clean space. For a high-spec environment, the process begins before you even touch a garment.

- Preparation: This starts with basic hygiene, ensuring you’ve removed all jewellery, make-up, and false eyelashes.

- The ‘PJ’ Phase: You begin by changing out of ‘civilian’ outer clothes and into lightweight separates, similar to medical scrubs.

- Head-Down Protocol: After a first pair of gloves is donned on freshly washed hands, you work from the head down. Since the head is the primary source of hair and skin cell shedding, you will secure a hairnet, face mask, goggles, and a beard snood where applicable.

Why Gowning Requires the Balance of Yoga

This is where the physical discipline comes in. When putting on the ‘gown’, usually an all-in-one coverall, the garment must never touch the ground. In a sterile situation, if a sleeve or leg accidentally trails on the floor, the item is considered compromised. It must be discarded, and the process started over.

This is logical when you consider that the floor is the highest-risk area for particulates. To prevent contamination, gowns are often packed inside-out, allowing you to use a re-disinfected gloved hand to slide into the suit without touching the sterile exterior.

The Yoga of the Step-Over Bench: Standing on one leg is an essential skill in the gowning room. As you pass the physical barrier, typically a step-over bench,you must sit to put on a clean shoe and then swing your leg over to the clean side. At no point should your feet or the suit touch the non-clean side of the barrier. A tacky mat on the clean side serves as a final fail-safe for any stray particles.

The ‘Two-Glove’ Technique and Final Validation

A vital part of cleanroom validation is the human protocol. On reaching your workstation, we recommend the "Two-Glove Technique." By wearing a second set of gloves in a different colour over the first, you can easily spot any micro-tears in the outer layer.

While you can purchase pre-packed double gloves, physically applying the second pair at the workstation is a better protocol. This ensures that any particles picked up on your hands while navigating the gowning room are covered before you handle sensitive components.

The gowning room is the most critical pressure-controlled area of the cleanroom build, ensuring no particles move upstream into the sterile zone. Gowning is truly an art form where the "little things" create the winning formula for compliance.

Cleanroom Gowning FAQs

The complexity of gowning is directly linked to the ISO 14644-1 cleanliness level of the environment. For an ISO 8 cleanroom, protocols usually involve basic hygiene, hairnets, and lab coats. However, for ISO 6 (Class B) environments and above, the process becomes far more stringent. This includes a full "head-down" protocol with face masks, goggles, beard snoods, and "PJ" separates (scrubs) worn beneath a full-body coverall to ensure maximum containment of human-generated particulates.

A step-over bench acts as a physical barrier between the "changing" and "clean" zones of the gowning room. To maintain integrity, you must sit on the bench and apply a clean shoe or overboot to one foot, then swing that leg over to the clean side without letting it touch the "dirty" floor. Repeat the process for the second leg. This "yoga-like" balance ensures that neither your clean footwear nor your cleanroom gown ever makes contact with a non-sterile surface.

The "two-glove" technique involves wearing a second set of gloves, ideally in a contrasting colour, over the first layer. This serves two purposes: first, it allows for easy visual detection of micro-tears or punctures in the outer glove; second, it ensures that any contaminants pic

In accordance with EU GMP Annex 1 standards, if any part of a cleanroom suit touches the floor during the gowning sequence, it is considered compromised. Because the floor is the primary collection point for particulates and microbes, a sleeve or trouser leg trailing on the ground poses a significant contamination risk to the final product. The operator must discard the item, re-sanitise their hands, and begin the gowning process from the start to ensure total compliance.