The Architect of Compliance: Navigating Complex Cleanroom Construction

The Architect of Compliance: Navigating Complex Cleanroom Construction

By Anthony Horsfield, Senior Project Manager

With nearly 30 years’ experience in Building Surveying and Construction Management, I’ve learned that the real work begins long before anyone arrives on site. A cleanroom isn’t just a construction project; it is a high-performance technical environment. To ensure success, we must bridge the gap between architectural integrity and the stringent ISO 14644-1 international standards for air cleanliness.

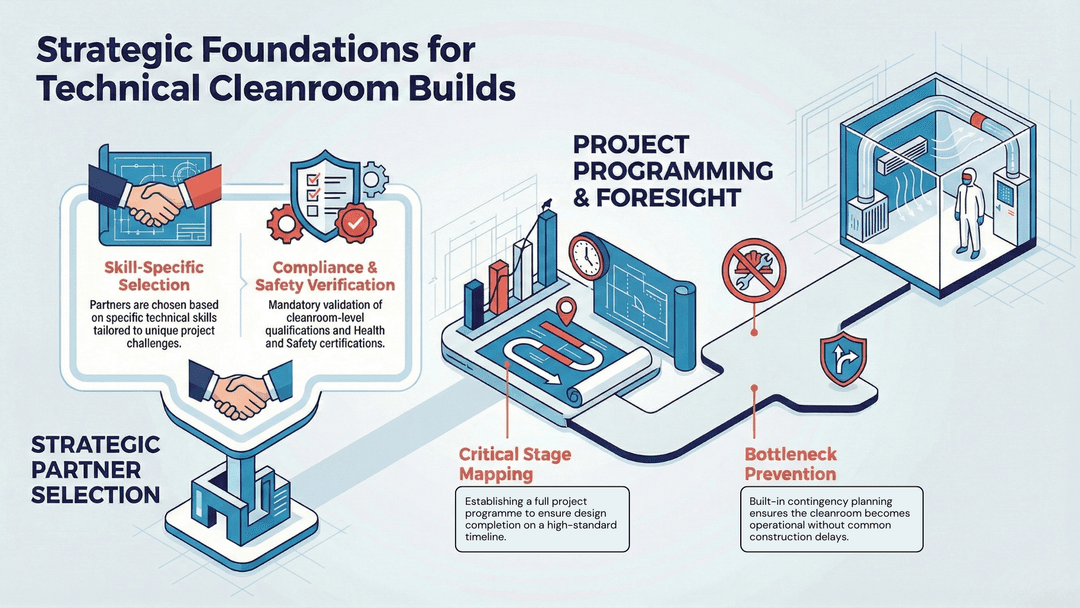

Strategic Planning and the Selection of Technical Partners

When a cleanroom build is greenlit, my first task is to identify and appoint the right team. Every project presents unique challenges, so we spend significant time selecting partners with the specific technical skills required for that exact environment.

Our selection criteria are rigorous. We ensure every partner has:

- Relevant Qualifications: Documentation proving they can work to the specific ISO level required.

- Safety Compliance: All necessary Health and Safety certifications.

- Proven Track Record: Experience in high-precision technical environments.

During this phase, I develop a full project programme. This sets out critical stages and timelines to ensure the design is completed on time to a high standard. While we build in contingency, this programme provides a clear indication of when the cleanroom will be finished and operational, preventing the common bottlenecks that plague complex construction projects.

Ensuring Seamless Teamwork: The Pre-Contract Meeting

Before the construction contract is finalised, we hold a pre-contract site meeting. The aim is a "forensic walkthrough" with the client to ensure a unified understanding of the project and to identify potential issues early.

Critical variables discussed include:

- Site Access & Logistics: How we move materials in without disrupting the facility.

- Verification of Measurements: Ensuring the 2D design matches the physical reality.

- Structural & Utility Constraints: Identifying power requirements and structural limits.

- HVAC Integration: Planning duct routes and the placement of heavy HVAC equipment.

On the first day on site, I meet with the client’s representative to run through the project and undertake site inductions. This ensures everyone understands the design and specification. This initial contact is essential; it enables different trades to build relationships so they can dovetail their work seamlessly.

Following Protocols and Minimising Adverse Impact

We often work directly within a customer’s existing, live premises. We are acutely conscious that sharing a workspace with a construction team can be disruptive. Teams calls and drilling are a difficult mix, so we communicate the daily task list with the onsite contact to ensure we respect your operations.

Safety and Custom RAMS

Safety is a massive part of my role. Before arriving on site, I produce and assess all Risk Assessments and Method Statements (RAMS). These are not generic documents; they are reflective of the specific tasks at hand and follow the latest HSE workplace risk management guidelines.

The Checklist: A key reference document is our bespoke checklist, tailored to each specific job. Depending on the complexity, this can range from 2 to 20 pages of rigorous quality and safety checks.

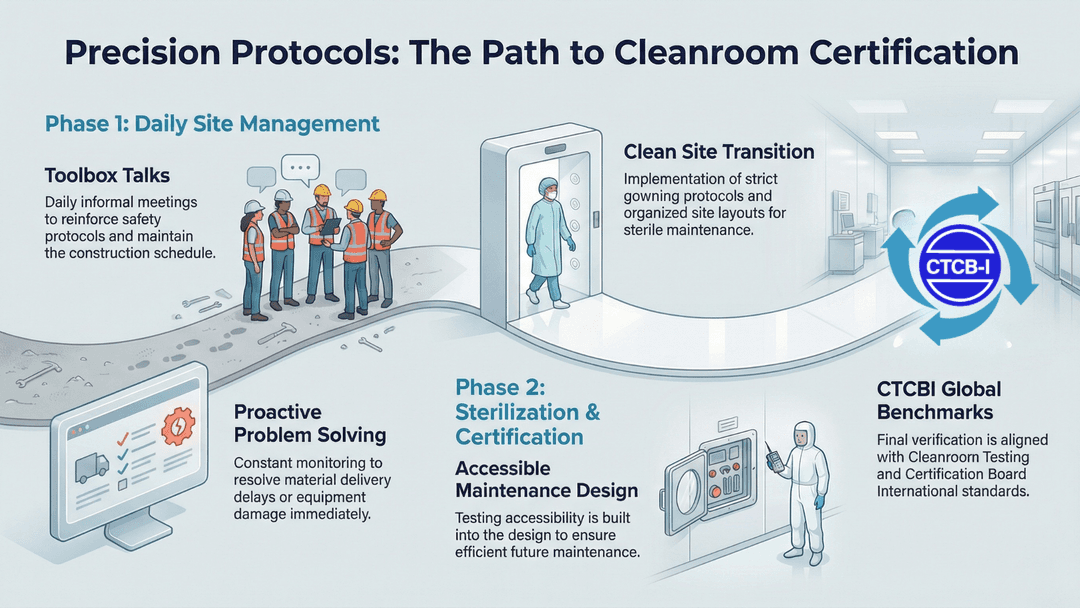

Toolbox Talks and the Transition to a Clean Site

Monitoring is a daily requirement. We hold frequent Toolbox Talks, short, informal meetings to discuss specific health and safety issues or reinforce plan details. Deliveries often pose challenges; if materials arrive late or damaged, it’s my job to solve those problems immediately to keep us on track.

As the build progresses, the site slowly transitions into a "Clean Site." We work closely with our teams to ensure they understand gowning protocols and keep the site organised. Because we both test and build, we integrate "easy testing accessibility" and maintenance into our design from day one.

Final Verification and Certification

Our knowledge ensures every facility is tested and certified in accordance with manufacturing design standards. To meet global benchmarks, we align our final verification with the standards set by the CTCB-I (Cleanroom Testing and Certification Board International).

Cleanroom Construction Frequently Asked Questions

The pre-contract meeting is a forensic audit of the physical space versus the technical design. We verify structural load-bearing capacities for heavy HVAC units, identify potential clashes between ducting routes and existing steelwork, and map out power requirements. By resolving these spatial conflicts in the 2D phase, we eliminate the need for costly "on-the-fly" modifications during the build.

We utilise a "Logistical Synergy" approach. This involves daily briefings with your onsite contact to schedule high-impact tasks, like drilling, concrete cutting, or material deliveries, outside of your peak production hours or sensitive meeting windows. Our strict adherence to site-specific RAMS ensures your staff remains safe and your core operations remain unaffected by the construction footprint.

A cleanroom that cannot be easily tested is a liability. We integrate testing accessibility into the design phase, ensuring that HEPA filters, monitoring probes, and pressure sensors are easily reachable for validation. By aligning our builds with CTCBI standards early on, we ensure the facility passes its final integrity tests without requiring structural changes to reach hidden components.

Once the envelope is sealed, we implement Contamination Control Protocols. This includes mandatory gowning for all trades, the use of non-shedding tools, and localized HEPA extraction for any minor adjustments. This transition is critical to ensure that when we perform the final particle count, the environment is already well within its target ISO class parameters.

Delivering Right First Time for Customer Satisfaction

In this industry, if you don’t get it right the first time, the cleanroom won’t be certified and the client cannot begin their work. It is a hugely rewarding job that requires a winning formula: a well-thought-out plan combined with a thorough, highly organised approach and a relentless attention to detail.

Want to know more about our cleanroom build services? Contact ISO Cleanroom and Let’s talk.

- Call: 0161 529 2816

- Email: sales@isocleanroom.co.uk