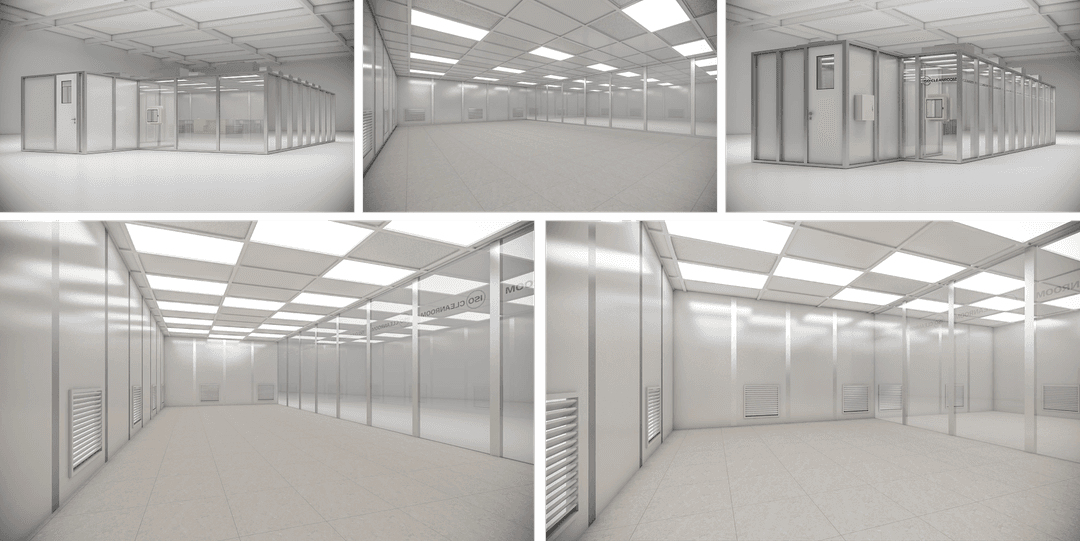

Cleanroom System Build

Cleanroom System Build

The ISO System is a permanent cleanroom system

The ISO System is designed to give you a gold standard clean environment coupled with maximum flexibility.

The specification will change depending on your application and site but there are a few consistent factors;

- H14 HEPA / G4 filtration

- +25 Pa cleanroom pressure

- +15 Pa gowning room pressure to an un categorized area

Benefits of the ISO System;

- Quick installation

- Easy upgrade between ISO levels

- Can be re-sited

The ISO System has been designed to make sure that additional environmental controls are easy to bolt on to this system. Controls you may require include;

- Temperature

- Humidity

- ESD / anti-static

- Light

- Particulate. ULPA

Validation

The ISO System can be designed and constructed to give you an ISO class 5 to ISO class 9 validation depending on your brief. The ISO System will be validated for air flow readings to ISO 14644-1:2015 and for airborne particle counts to ISO 14644-2:2015. A full report will be provided as an electronic file.

Materials

We use extruded aluminium to form the frame which means that the frames are flexible. We have the ability to extend, reconfigure or move the cleanroom as requirement change in the future. There is a variety of options available to us for the wall infill material depending on your process. As a standard we use a mixture of glass as it has excellent electrical insulating properties and aluminium panel where a more robust or solid finish is required.

We choose to work with aluminium over cheaper options as it is corrosion resistant and has a high electrical conductivity making it easy to earth. Another benefit of aluminium and glass is that they are widely recycled.

The order process

Following a conversation with the customer we will provide a budgetary cost for the cleanroom. If this is deemed as acceptable, we will then move to more detailed conversations about the remit of the project and issue a quotation. The quotation details the ISO Cleanroom system, installation, validation, maintenance package, any additional services or items and the expected lead time. A site meeting maybe required depending on the complexity of the site.

Should this be acceptable the customer will raise a purchase order and following the acceptance of this order the drawings are then submitted to the customer for approval. Once the customer has signed off the drawings, production begins. The installation date for the cleanroom will then be confirmed.

The site will have been prepared prior to the ISO System arriving. ISO Cleanroom will start the installation. Further payment is usually required prior to the ISO System arriving to site for installation.

Once the installation is complete, the ISO System will be validated for air flow readings to ISO 14644-1:2015 and for airborne particle counts to ISO 14644-2:2015. There are many optional additional tests such as filter integrity testing and airflow (smoke visualisation) which will be discussed with you at quote stage.

The successful validation report being accepted by the customer is the sign off point.

Full turnkey package

Many of our customers prefer the convenience of one company providing all services associated with the cleanroom build and commission. ISO Cleanroom can provide all required electrics, compressed air lines, water and gasses to the cleanroom. We can supply all stainless-steel gowning room furniture including step over benches, gown storage, stainless-steel lockers and PPE dispensers. Inside the cleanroom we regularly provide stainless steel benches and other laboratory furniture.

Industry-specific examples

| Industry type | ISO range | ISO type | Airflow rate (Avg. air changes per hour) | Controls | Special features |

| Aerospace | ISO 5 14644-2:2015. | System | 240 | ESD | No outgassing materials |

| Automotive | ISO Class 8 14644-2:2015 | System | 30 | Robust | |

| Defence | ISO 6 14644-2:2015 | System | 150 | ESD | |

| Electronics | ISO 7 14644-2:2015. | System | 90 | ESD | |

| Engineering | Dust free | Enclosure | 30 | Portability | |

| Energy and Nuclear | ISO 7 14644-2:2015. | Enclosure | 90 | Soft side walls for cable connection North sea | |

| Food | ISO 8 14644-2:2015 | System | 30 | ||

| Healthcare | ISO 5 14644-2:2015 | System | 240 | ||

| Medical device | ISO 6 14644-2:2015 | System | 150 | ||

| Pharmaceutical | ISO 6 14644-2:2015 | System | 150 | Temp, Humidity, HVac | |

| Photolithography | ISO 6 14644-2:2015 | System | 150 | Light | Yellow (amber) light option |

| Semi-conductor | ISO 5 14644-2:2015 | System | 240 |