The connection between working in an ISO classified cleanroom and the ancient art of Yoga…

The connection between working in an ISO classified cleanroom and the ancient art of Yoga…

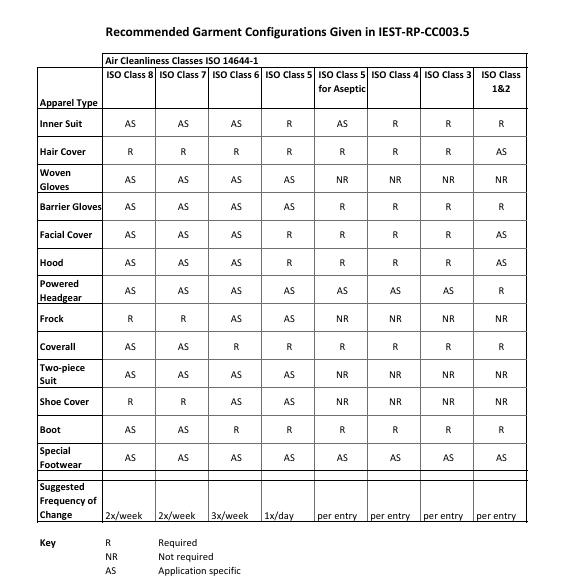

It can be as simple as basic hygiene, hair net, shoe covers and a lab coat for ISO 8 processes and manufacture, up to full covering including masks for an ISO 6 and above environment.

According to EU GMP Annex 1 and ISO 14644-1, it’s all about risk assessment: if you’re working on ready prepared components at a bench top with nothing below that level … do you need more than a simple coverall and gloves? The question to ask yourself is: where is the sensitivity in your individual product item and what part of it do you need to protect from contamination?

Of course, you may need to be much more stringent: if your product is for the wafer fab industry such as semi-conductor production it will be about protecting everything at every stage! The same can often apply in engineering: if the pieces are large and you will be moving above, below and all around them, the chances are you will need to fully protect them from human contamination through stringent PPE.

Pharma and medical items also have a whole range of gowning protocols that apply specifically for their industries, often including additional anti-fungal hand sprays and sterile and non-sterile gown options.

So what are the stages in a rigorous ‘gowning’ process?

‘Gowning’ is far more comprehensive than the name suggests…it’s an all-embracing term covering each stage of your preparation for entering a cleanroom: the various items of wear, the techniques for putting them on and how you physically step into the clean space.

For an ISO 6 or Class B environment, you could start by changing out of your ‘civilian outer clothes’ and putting on your ‘PJs’ – lightweight separates a bit like medical scrubs (having first ensured you’ve had a bathroom break). You’ll then don a first pair of gloves (on your ‘just washed’ hands) to protect your clean items as you go, and then work from your head down…It’s obvious really, the head has hair (which comes off very easily) and skin cells to shed while other non-exposed parts of the body can be protected by clothes. The kit here might involve a hairnet, face mask, goggles, a beard snood for facial hair– and you will also have removed any jewellery and make-up, including the ever popular false eyelashes.

This is where the yoga comes in…

Then it is time for the ‘gown’, usually an all-in-one suit which needs to be put on without any of it touching the ground… In a sterile situation, if an arm accidentally trailed on the floor while you were getting your feet in, it would mean you’d have to take it off, throw it in the bin and start all over again.

Again, it’s logical when you think about it: the floor is the dirtiest place in the cleanroom – or probably anywhere else – and you’ve just touched it with a sleeve - which when your arm is inside it, will be right next to where you are working…it’s a risk.

Gowns can be packed in such a way as to help the wearer dress – they will already be inside out and ready to slide into, so you can use your gloved hand (which you will often have re-disinfected) to fold them down over your cuff without touching anything non-sterile.

And then there are the legs, and that’s where the Yoga (or Pilates or any other balance exercise) comes in: the ability to stand on one leg is essential as again, no part of the suit must touch the floor.

That’s nearly all of your items: just shoes to go on as you pass the physical barrier, usually a ‘step over bench’ at the door of the cleanroom: you sit on it to put a clean shoe on and then swing your leg over for the second – shoes only touch the clean side (hands and feet only ever touch the inside of the protective clothing). There will often be a tacky mat on the clean side, just in case any particles have attached to the underside of those shoes – and another important feature is a mirror so you can have a quick visual check to ensure there is nothing out of place … an escaped wisp of hair etc. And that’s before you use that anti-fungal spray and a final disinfect of the gloved hands….

On reaching your workstation you might don your second set of gloves: a different colour from your first layer as it means you can easily spot any tears in the outer glove.

Two glove technique

With gloves, you can even buy packs with one inside the other already – although it is actually better to physically have two… the first pair when you put your gown on - but then you can touch so many things as you make your way to your work station, putting on another pair when you get there is a better protocol. The gowning room is a vital part of the cleanroom – you have to be able to control the particles as you prepare to enter: it will be a pressure-controlled area (so no particles go upstream). I tell people gowning is an art, and it can be all about the little things: although sterile is much harder than non-sterile, many of the techniques and protocols are simply good practice. If you want to look into this topic further, why not take a look at some of these videos available on line – admittedly for the higher end of cleanrooms, but both are an interesting watch!

— Toni HorsfieldFor GMP

And for ESD https://www.youtube.com/watch?v=mxQjo17aTqA

Another great resource is the book ‘Basic Cleanroom Technology’ by one of our industry’s founding fathers William (Bill) Whyte which offers broad brush guide to what you need to wear depending on the ISO Cleanroom Classification.