Going global: HEPA filters and a new standard

Going global: HEPA filters and a new standard

As international air filter and air pollution control system manufacturer Camfil states in its blog post on this subject, there would be no computers or medicine without HEPA filters. https://www.camfil.com/en/insights/life-science-and-healthcare/history-and-facts-about-hepa-filters

Trusting the validity of these filters through robust manufacturing techniques and rigorous testing methods is vital.

The first standard setting out how manufacturers should test these high efficiency filters and report their efficacy was published in 1956:American standard MIL-STD-282. In 1994, Australian standard AS 113.9-1973 extracted the air, filter testing to its own standard, AS 4260. In 1998, the European standard EN 1822 was first published. The Japanese have standard JIS K 3801, we could go on…

In the early 2000s, there was an increasing demand for consistency in air quality standards across the world. The global ISO 29463 parts 1-5 was published in October 2011. In August 2024. ISO published the third revision of ISO 29463-1:2024, part 1,which establishes classification of filters based on their performance. https://www.iso.org/standard/84367.html

HEPA filters and the new standard

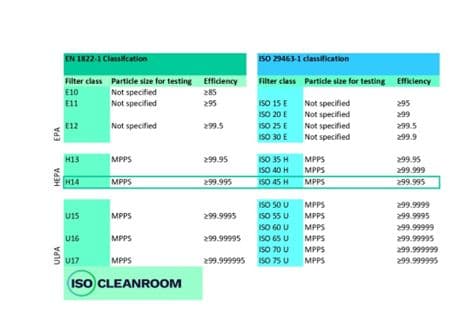

In the second edition of ISO 29463-1:2017,the world was introduced to a new classification system. It defines 13 different filter classes ranging from ISO 15 E to ISO 75. (The ISO was designed to accommodate the practices of other national standards including those from the US and Japan.)

As you can see from the tablebelow, the filter we in Europe would describe as aHEPA H14 under EN 1822, is equivalent to an ISO 45 H in the new ISO 29463-1.

Another key difference between the European EN 1822-1 and ISO 29463-1 is the testing methodology permitted in each standard. There are five permitted tests in ISO 29463-1,whereas there are only three in EN 1822-1, making the latter the more stringent standard.

As a recent article in the journal for Chartered Institution of Building Services Engineers explains: ‘In Europe, ISO 29463 co-exists with a revised EN 1822 standard that maintains its own equivalent classification system for air filters so retaining the designations of HEPA filter classes that are familiar to many – H13 and H14 – and having test methods that are in accordance with ISO 29463 Parts 2-5.

‘A key difference between ISO 29463 and various national standards is that, instead of testing mass relationships or total concentrations, the assessment of filter efficiency is based on particle counting at the most penetrating particle size (MPPS), using a standard aerosol, which will depend on the particular filter media and construction.’

For the full article, seehttps://www.cibsejournal.com/technical/understanding-hepa-filters/

Whilst our European standard always used the MMPS, this is another move the ISO 29463-1makes towards a unified global standard.

A worldwide standard

The new ISO 29463-1:2024is a global standard, and while the principles behind it are similar to its European counterpart, it offers a more universal framework, aligning testing methodologies and classifications across international markets. In particular, ISO 29463 part 1 offers clearer definitions for filter efficiency and particle capture, making it easier for manufacturers and consumers to compare filter performance on a global scale.

Consistency will be the future

Keeping a close watch on industry-wide commentary around the new standard, ISO Cleanroom founder and Managing Committee Member of the Contamination Control Network (CCN) Toni Horsfield says:

What is important is that designers, manufacturers and customers are checking the certification of their filters. All HEPA and ULPA filters should come with their own individual test certificate. This is a vital piece of paperwork that should be checked to prove its authenticity and performance. The ISO standard keeps it simple: if companies deal with other parts of the world, it means they won’t need to specify different filters according to varying standards in separate regions, and when purchasing HEPA filters, buyers will have the confidence of knowing performance criteria is universally understood and verified.

— Toni HorsfieldTo contact Toni at ISO Cleanroom, call 0161 529 2816.